OUR SOLUTIONS

PRECISION MILL MANUFACTURERS WITH INDEPENDENT RESEARCH AND DEVELOPMENT AND MANUFACTURING CAPABILITIES

- Sectors

- Technologies

HIGH VALUE-ADDED SOLUTIONS

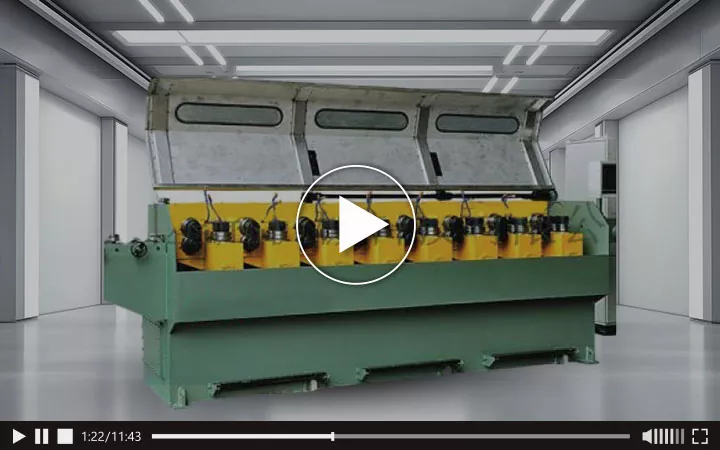

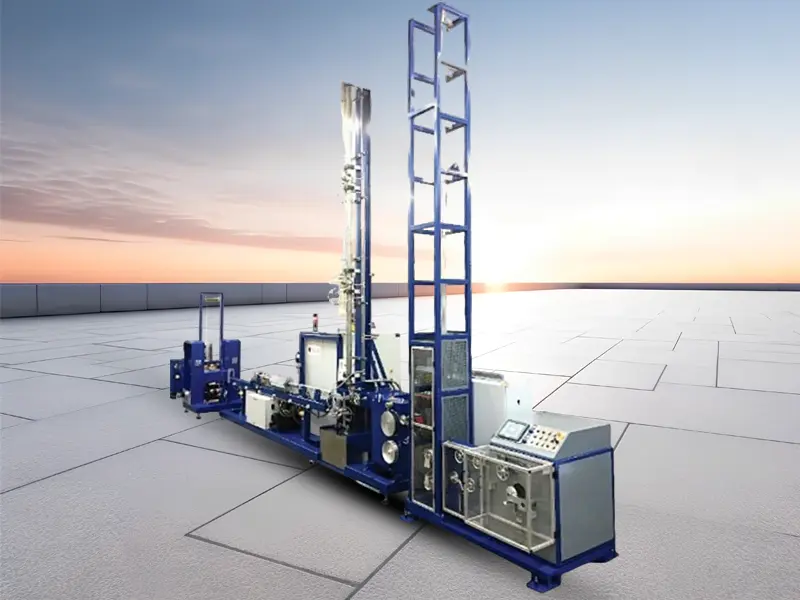

Advanced Manufacturing System

Equipped with Japanese CNC machining centers, laser precision measurement tools, and fully automated assembly lines.

Integrated R&D centers, machining workshops, and quality control labs ensure end-to-end production.

Innovation Milestones

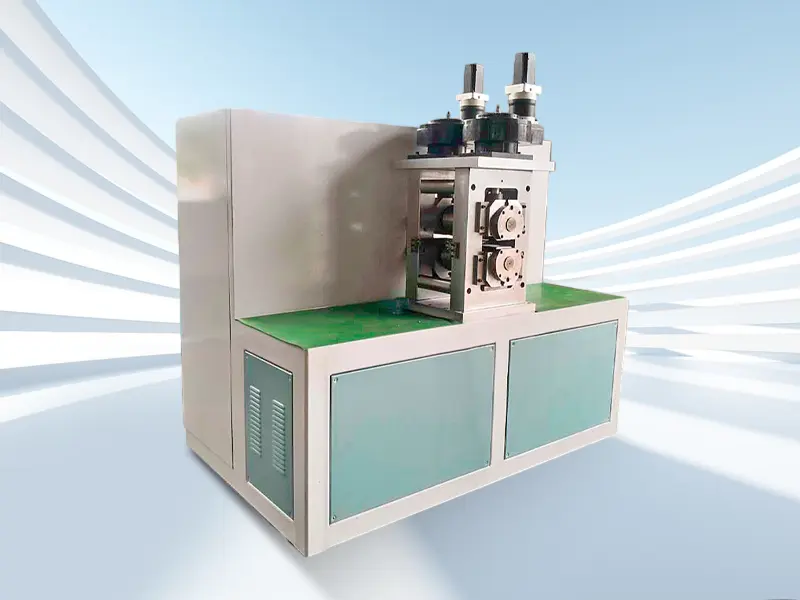

Polygonal Wire Automatic Feeding Device (Patent No. ZL 2020 228400538), filing domestic technology gaps.

Breakthrough Busbar Rolling Equipment technology.

FIRST-LEVEL CUSTOMERS

CLOSER TO YOU

SINCE 2004

It has been deeply engaged in the field of metal forming for 16 years, and has now become a leading manufacturer of intelligent precision rolling mill and photovoltaic welding belt equipment in China

TALENT STRUCTURE

As of 2025, the Company employs 60 professionals, with R&D personnel accounting for over 30% of the workforce.

INNOVATION MILESTONES

Holds 50+ patents, fills the national gap "polygon wire automatic feeding device", breakthrough "bus strip calendering equipment" technology.

Jiangsu Youzha Machinery Co., Ltd.

About Us

2025-04-27

European cutting-edge technology helps! Innovate photovoltaic ribbon manufacturing technology with Plasmait

Core highlights: Redefine metal processing efficiency and environmental standards

2025-03-12

What are the advantages of single mill

Single-pass mill is a equipment that completes rolling deformation only through the roll once in the rolling process, and its advantages are mainly reflected in the following aspects:

2025-03-12

Introduction to the main safety technology of steel rolling mill manufacturer

At present, steel rolling is widely used in industry, which mainly includes two types, namely hot rolling mill and cold rolling mill. And there are many kinds of products and different specifications. However, rolling steel in the shape of the billet pressure processing, need to adopt some safety techniques. So, do you know what the main safety technologies are?

2025-03-12

Rolling mill pressing system setup operation and advantages

In today's finishing mill pressing system, the belt pulley of the synchronous mechanism is wrapped in a screw, the tooth belt mechanism of the tooth belt is arranged on the side wall of the fixed housing, the driven belt pulley mechanism of the tooth belt is wound on the fixed shaft, the fixed axis around the driven belt pulley and the axis of the relative rotatable rotating fixed shaft move upward and downward.

2026-01-05

How Can a Complex Profile Rolling Mill Reduce Scrap While Holding Tight Tolerances?

Complex profiles look great on a drawing—until the first trial run exposes twist, waviness, edge cracking, inconsistent dimensions, or a surface finish that doesn’t meet spec.

2025-12-30

What are the core values of photovoltaic welding strip rolling mill

The photovoltaic welding strip rolling mill is the core equipment for photovoltaic welding strip production, and its core value runs through the four core dimensions of welding strip quality, component performance, production efficiency, and industry adaptability. It directly determines whether the welding strip can meet the strict requirements of photovoltaic modules (especially high-efficiency modules), and is also the key to cost reduction and efficiency improvement of the production line. The core value can be summarized as 5 cores+2 extensions, accurately landing and meeting the industry's needs: