- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

- Esperanto

- Afrikaans

- Català

- שפה עברית

- Cymraeg

- Galego

- Latviešu

- icelandic

- ייִדיש

- беларускі

- Hrvatski

- Kreyòl ayisyen

- Shqiptar

- Malti

- lugha ya Kiswahili

- አማርኛ

- Bosanski

- Frysk

- ភាសាខ្មែរ

- ქართული

- ગુજરાતી

- Hausa

- Кыргыз тили

- ಕನ್ನಡ

- Corsa

- Kurdî

- മലയാളം

- Maori

- Монгол хэл

- Hmong

- IsiXhosa

- Zulu

- Yoruba

- অসমীয়া

- ଓଡିଆ

- Punjabi

- پښتو

- Chichewa

- Samoa

- Sesotho

- සිංහල

- Gàidhlig

- Cebuano

- Somali

- Тоҷикӣ

- O'zbek

- Hawaiian

- سنڌي

- Shinra

- Հայերեն

- Igbo

- Sundanese

- Lëtzebuergesch

- Malagasy

European cutting-edge technology helps! Innovate photovoltaic ribbon manufacturing technology with Plasmait

2025-04-27

Core highlights: Redefine metal processing efficiency and environmental standards

1. Three-strong joint technology endorsement

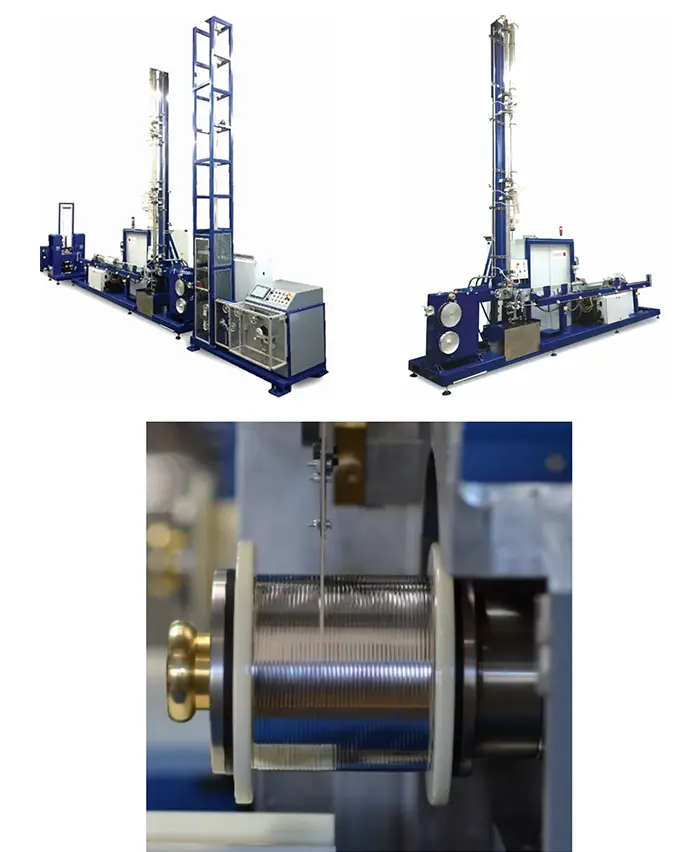

The dual-line plasma annealing tin coating production line jointly developed by Austrian Plasmait (official website: plasmait.com)\ROCKTA and GRM deeply integrates European cutting-edge technology and localized production needs, providing a one-stop solution from raw materials to finished products.

2. Flux-free · Green smart manufacturing

• Plasma activation technology completely replaces traditional flux, eliminates chemical residues and wastewater treatment problems, and achieves metal surface treatment without oxidation, mud, and pinholes.

• Micron-level tin coating accuracy: thickness 3-40μm, covering customized alloy requirements such as Sn/Pb/SnAgC/SnBi, smooth and bright coating, corrosion resistance and welding performance leading the industry.

2. Efficient integration · intelligent production

Integrated online wire drawing/rolling and annealing processes, supporting seamless connection with front-end processes. Equipped with HMI touch screen PLC control system and computer quality database, real-time monitoring of surface quality to ensure production stability and product consistency.

3. Ultra-high-speed production capacity and flexible adaptation

• Dual-line independent operation architecture: supports 2x pay-off → 2x wire drawing/rolling → 2x plasma treatment (cleaning/activation/annealing) → 2x tin coating → 2x take-up, the equipment length is 6-15m, the width is ≤2.5m, and the area is compact.

• Extreme speed and production capacity: The maximum speed of a single line is 600m/min (the photovoltaic welding ribbon dedicated line can reach 300m/min), the maximum production capacity is 800kg/h, and it is suitable for copper/copper-clad aluminum/copper-clad steel wires, bars, narrow strips and photovoltaic welding ribbons with a width of 0.1-30mm.

Technical Parameters Overview

Project Specifications

Applicable Materials Copper/Copper Clad Aluminum/Copper Clad Steel Wire, Rod, Narrow Strip, PV Ribbon, etc. (0.1-30mm)

Tin Coating Type Interconnection Strip (0.3-3.0mm Width), Busbar (3.0-8.0mm Width)

Core Process Plasma Activation (Replacement of Flux) + Online Annealing + High-Precision Tin Coating

Tin Coating Thickness 3-40μm (Customized Alloys such as Sn/SnPb/SnAgC/SnBi)

Material Properties Yield Strength after Annealing ≥50MPa Rp0.2!, Adjustable Hardness (from Soft to High-Strength)

Cooling System Nitrogen/Synthesis Gas Precooling + High-Efficiency Cooling Channel, Precise Temperature Control

Environmentally Friendly Design No chemical reagents, no oxides produced, supporting sustainable development goals

Six major application scenarios empower global industries

1. New energy: photovoltaic module interconnection strips/bus strips (compatible with PERC/HJT/TOPCon batteries)

2. New energy vehicles: battery pack cables, motor winding conductors, air conditioning capillaries (0.3-10mm diameter)

3. Electronics and electrical: power signal cables (solid wire/square wire/texture wire/bundle wire), precision instrument wires

4. Aerospace: high temperature resistant alloy wires, lightweight conductive parts

5. High-end manufacturing: medical equipment coating catheters, automotive high-voltage wiring harnesses

6. Traditional upgrades: air conditioning refrigeration pipelines, transformer winding wires