- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

- Esperanto

- Afrikaans

- Català

- שפה עברית

- Cymraeg

- Galego

- Latviešu

- icelandic

- ייִדיש

- беларускі

- Hrvatski

- Kreyòl ayisyen

- Shqiptar

- Malti

- lugha ya Kiswahili

- አማርኛ

- Bosanski

- Frysk

- ភាសាខ្មែរ

- ქართული

- ગુજરાતી

- Hausa

- Кыргыз тили

- ಕನ್ನಡ

- Corsa

- Kurdî

- മലയാളം

- Maori

- Монгол хэл

- Hmong

- IsiXhosa

- Zulu

- Yoruba

- অসমীয়া

- ଓଡିଆ

- Punjabi

- پښتو

- Chichewa

- Samoa

- Sesotho

- සිංහල

- Gàidhlig

- Cebuano

- Somali

- Тоҷикӣ

- O'zbek

- Hawaiian

- سنڌي

- Shinra

- Հայերեն

- Igbo

- Sundanese

- Lëtzebuergesch

- Malagasy

Strip Rolling Mill

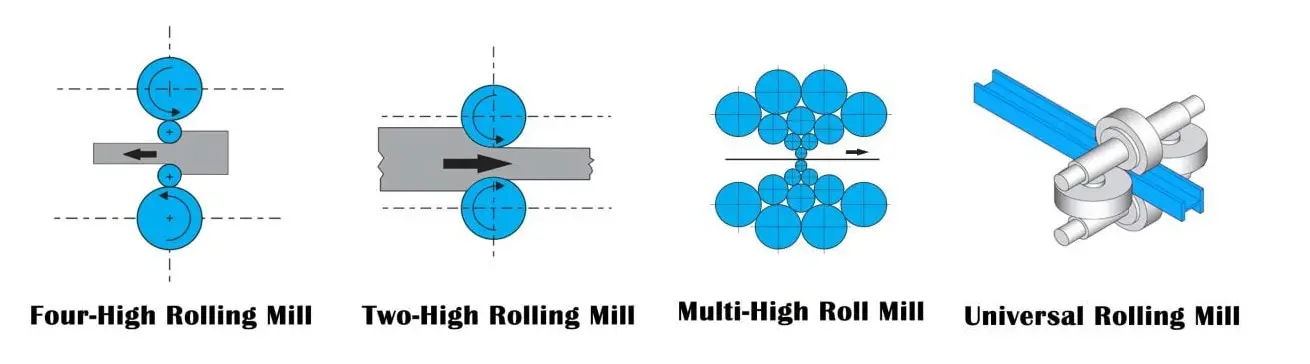

Rolling Mills by Roll Quantity

GRM Precision Engineering Solutions

Choosing the Right Strip Rolling Mill is Choosing Future Competitiveness

No matter what your needs are:

Stable equipment for large-scale production

Ultra-precision rolling for high-end material R&D

Smart upgrades for traditional production lines

GRM manufacturer provide comprehensive rolling solutions, from two-high basic models to advanced twenty-high mills, ensuring full material coverage—from carbon steel and stainless steel to non-ferrous metals and specialty alloys.

Why Roll Quantity Matters

Core Value Proposition

The number of rolls determines precision, efficiency, and material compatibility. GRM supplier delivers customized solutions from basic forming to ultra-thin foil production, with real-time computer-controlled monitoring for unmatched consistency.

- View as

6-Roll Rolling Mill

The 6-roll rolling mill is an advanced metal rolling equipment developed on the basis of the four high rolling mill, consisting of upper and lower working rolls, upper and lower intermediate rolls, and upper and lower support rolls. Widely used in the production of plate and strip materials in industries such as steel and non-ferrous metals, it can produce high-precision plate and strip materials for automotive manufacturing, home appliances, electronics, aerospace, and other fields.

Read MoreSend Inquiry2-Roll Rolling Mill

A 2-roll rolling mill is a rolling mill consisting of two horizontal rollers arranged vertically in the same plane, mainly used for metal rolling. The 2-roll rolling mill has a simple structure and reliable operation. It is driven by a DC motor and used in a two roll reversible roughing mill. It can roll steel ingots back and forth into various rectangular billets. A continuous rolling mill is composed of several 2-roll machine bases driven by DC or AC motors in groups, which can produce steel billets and sections with high productivity

Read MoreSend Inquiry20-Roll Rolling Mill

The 20-Roll Rolling Mill is a high-precision rolling mill used for cold rolling metal sheets and ultra-thin strips. It is mainly used for the production of thin and ultra-thin strips such as cold-rolled stainless steel, silicon steel, high-strength metals and alloys. It almost undertakes 96% of the world's stainless steel production and is widely used in industries such as automobiles, home appliances, electronics, aerospace, etc. that require high precision and quality of sheet metal

Read MoreSend Inquiry4-Roll Rolling Mill

A 4-Roll Rolling Mill is a metal processing equipment consisting of two parallel, smaller diameter horizontal work rolls and two larger diameter support rolls used to support the work rolls. High relative stiffness, which can effectively control the dimensional accuracy and plate shape of the rolled piece; The large amount of compression can cause significant deformation of metal materials; Low rolling force, capable of rolling thinner plates, suitable for various metal materials such as plain carbon steel, alloy steel, stainless steel, copper, aluminum, etc

Read MoreSend Inquiry