- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

- Esperanto

- Afrikaans

- Català

- שפה עברית

- Cymraeg

- Galego

- Latviešu

- icelandic

- ייִדיש

- беларускі

- Hrvatski

- Kreyòl ayisyen

- Shqiptar

- Malti

- lugha ya Kiswahili

- አማርኛ

- Bosanski

- Frysk

- ភាសាខ្មែរ

- ქართული

- ગુજરાતી

- Hausa

- Кыргыз тили

- ಕನ್ನಡ

- Corsa

- Kurdî

- മലയാളം

- Maori

- Монгол хэл

- Hmong

- IsiXhosa

- Zulu

- Yoruba

- অসমীয়া

- ଓଡିଆ

- Punjabi

- پښتو

- Chichewa

- Samoa

- Sesotho

- සිංහල

- Gàidhlig

- Cebuano

- Somali

- Тоҷикӣ

- O'zbek

- Hawaiian

- سنڌي

- Shinra

- Հայերեն

- Igbo

- Sundanese

- Lëtzebuergesch

- Malagasy

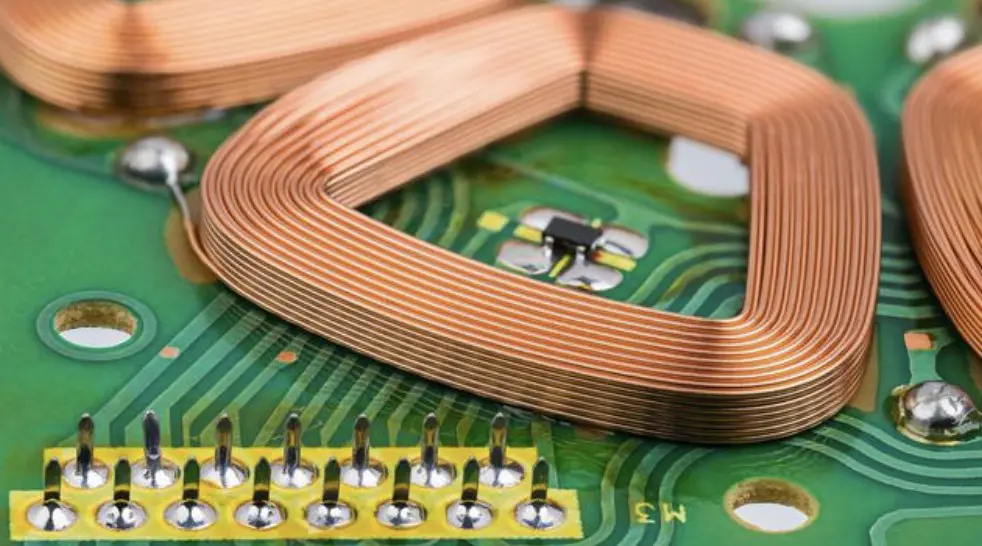

Electromagnetic Wire Rolling Mill

Send Inquiry

GRM supplier offers high-precision electromagnetic wire rolling mill, designed for precision forming of rectangular magnet wires. The equipment uses extrusion or cold rolling processes, and ensures that the wire has precise corner shapes through multiple rolling passes, and can be insulated with enameled, paper or polyester wrap. The rolling mill has a high-end thickness and width control system to ensure excellent coil density and insulation quality, and is widely used in the manufacture of high-performance electrical equipment such as motors, transformers, and inverters.

Key Advantages

✅ High conductivity:Optimized for magnet wire manufacturing to reduce resistivity loss

✅ High surface finish:Suitable for high-precision coil windings, compatible with insulation coating processes

✅ Ultra-Precision Rolling:The rolling tolerance is strictly controlled, suitable for mass production.

✅ High-Speed Efficiency:600m/min continuous operation

Applications

|

Industry |

Solution & Value |

|

Motor Manufacturing |

15% copper loss reduction with precision rectangular wires |

|

Transformers |

98% fill rate for optimized conductive efficiency |

|

New Energy |

10kW/cm³ power density for EV inverters |

|

Inductors |

enhanced electromagnetic performance |

Technical Specifications

|

Parameter |

Specification |

|

Material |

Copper |

|

Input Dimensions |

Thickness 0.8-8.0mm, Width 2-25.0mm |

|

Output Sections |

20mm² (customizable) |

|

Tolerance |

± 0.01mm |

|

Rollers |

Tungsten carbide rolls (Φ160-280mm) |

Layout drawing of electromagnetic wire rolling mill 2D/3D

Optional Upgrades

Online annealing and tin coating system

Why Choose Us?

✅ 3x longer roll life with patented stand design

✅ Integrated annealing & coating modules

✅ 24/7 remote maintenance via IoT

Contact Us for Customized Solutions

Email: solutions@grm-machinery.com

Powering Tomorrow’s Manufacturing – GRM Mills Redefine Precision Rolling