- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

- Esperanto

- Afrikaans

- Català

- שפה עברית

- Cymraeg

- Galego

- Latviešu

- icelandic

- ייִדיש

- беларускі

- Hrvatski

- Kreyòl ayisyen

- Shqiptar

- Malti

- lugha ya Kiswahili

- አማርኛ

- Bosanski

- Frysk

- ភាសាខ្មែរ

- ქართული

- ગુજરાતી

- Hausa

- Кыргыз тили

- ಕನ್ನಡ

- Corsa

- Kurdî

- മലയാളം

- Maori

- Монгол хэл

- Hmong

- IsiXhosa

- Zulu

- Yoruba

- অসমীয়া

- ଓଡିଆ

- Punjabi

- پښتو

- Chichewa

- Samoa

- Sesotho

- සිංහල

- Gàidhlig

- Cebuano

- Somali

- Тоҷикӣ

- O'zbek

- Hawaiian

- سنڌي

- Shinra

- Հայերեն

- Igbo

- Sundanese

- Lëtzebuergesch

- Malagasy

20-Roll Rolling Mill

Send Inquiry

GRM 20-Roll Rolling Mill is a Roan clamp type mill, which adopts advanced hydraulic automatic control technology and combined with roller control to achieve excellent plate shape and thickness accuracy. The equipment can flexibly switch between 20-roll and 8-roll modes, suitable for precision rolling of materials of different thicknesses. Its high efficiency, energy saving and easy operation make it an ideal choice for high-end metal processing industry.

Industry applications

• Precision rolling of stainless steel, carbon steel, copper, aluminum and other metal sheets

• Aerospace High-precision alloy sheet production

• Electronic manufacturing Ultra-thin metal material production

• New energy Lithium battery foil, photovoltaic industry precision strip manufacturing

• Automobile manufacturing Lightweight metal material processing

Applications

|

Field |

Scenarios |

|

Precision stainless steel manufacturing |

Mirror stainless steel strip (Ra≤0.01μm): high-end home appliance panels, elevator decorative panels |

|

New energy material processing |

Mirror stainless steel strip (Ra≤0.01μm): high-end home appliance panels, elevator decorative panels |

|

Aerospace |

Nickel-based alloy sheet for aircraft engines |

|

Cutting-edge material development |

Metallic layered composites, nanocrystalline ribbons |

Core advantages

• Ultra-thin rolling: minimum thickness can reach 0.001mm (1μm)

• Ultra-high precision: servo hydraulic AGC + X-ray/contact thickness gauge, thickness accuracy up to ±0.002mm

• Flexible rolling: twenty rollers/eight rollers can be switched to meet different thickness requirements

• Small footprint, easy to install: compact structure design, easy to operate, can be operated by one person independently

Technical Parameters

| project | Specifications |

| Rolling mill type | Twenty-high hydraulic rolling mill |

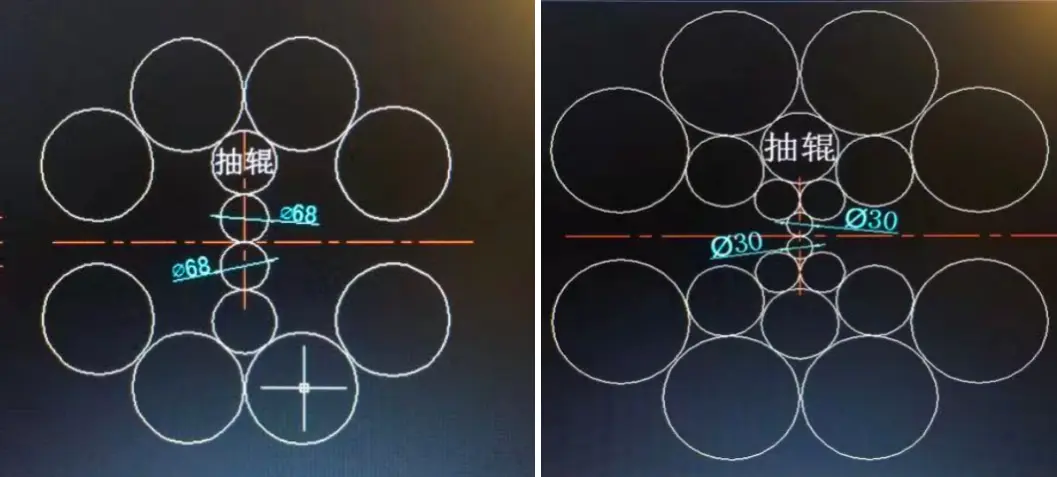

| Working roll diameter | Eight roller mode: Φ68mm |

| Twenty roller mode: Φ30mm | |

| Feed thickness | 1.2mm |

| Minimum finished product thickness | 0.03mm |

| Maximum bandwidth | 280mm |

| Rolling speed | 0-120m/min |

| Main motor power | 90KW (AC frequency conversion + reducer) |

| High tension motor | 75KWx2 sets (1:18 reduction) |

| Small tension motor | 7.5KWx2 sets (1:3.54/1:11.1 reduction) |

Why choose us?

• Innovative technology: industry-leading hydraulic AGC + intelligent constant tension control to ensure ultimate precision

• High cost performance: lower energy consumption and more convenient maintenance compared to traditional twenty-high mills

• High production efficiency: large single press volume, reducing the total number of passes and annealing times, and improving productivity

• Safe and stable: full AC frequency conversion control, low noise, with multiple safety protections

Contact Us for Customized Solutions

Email: solutions@grm-machinery.com

Powering Tomorrow’s Manufacturing – GRM Mills Redefine Precision Rolling