- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

- Esperanto

- Afrikaans

- Català

- שפה עברית

- Cymraeg

- Galego

- Latviešu

- icelandic

- ייִדיש

- беларускі

- Hrvatski

- Kreyòl ayisyen

- Shqiptar

- Malti

- lugha ya Kiswahili

- አማርኛ

- Bosanski

- Frysk

- ភាសាខ្មែរ

- ქართული

- ગુજરાતી

- Hausa

- Кыргыз тили

- ಕನ್ನಡ

- Corsa

- Kurdî

- മലയാളം

- Maori

- Монгол хэл

- Hmong

- IsiXhosa

- Zulu

- Yoruba

- অসমীয়া

- ଓଡିଆ

- Punjabi

- پښتو

- Chichewa

- Samoa

- Sesotho

- සිංහල

- Gàidhlig

- Cebuano

- Somali

- Тоҷикӣ

- O'zbek

- Hawaiian

- سنڌي

- Shinra

- Հայերեն

- Igbo

- Sundanese

- Lëtzebuergesch

- Malagasy

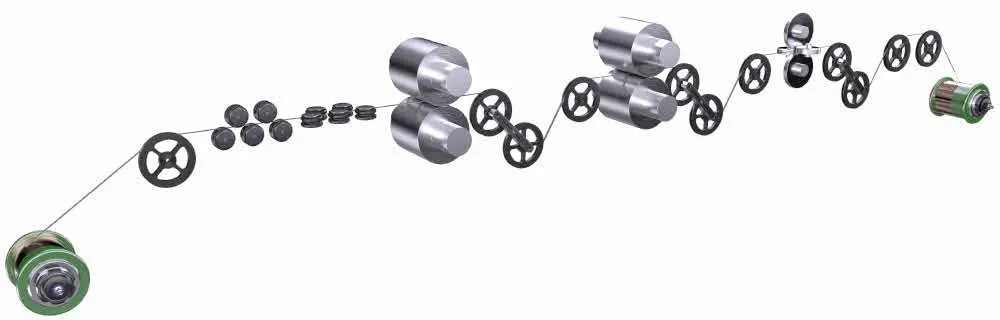

Flat Wire Rolling Mill

As a manufacturer of innovative high-tech machines, HMPRoling provides a wide range of high-precision rolling mils for producing rectangular, square and profile geometries. State-of-the-art machine technology ensures minimum downtime and maximum output.

Based on our standard range, the machines are customized towards customer and material requirements.

FLAT ROLLING & PROFILE ROLLING

In this process, round wires are rolled into fat and / or special shaped geometries. During the process, the wire is rolled in several stages vertically as well as horizontally (edge rolling). A huge range of different profiles is applicable.

CONFIGURATION:

| Mill type | FPW 9o | FPW 200 | FPW 400 | FPW 600 | FPW8o0 | FPW 1000 | FPW1200 | |

| 2Hi Roll Sets | Rolling force [kN] | 90 | 200 | 400 | 600 | 800 | 1000 | 1200 |

| Roll diameter/1[mm] | 80 | 140 | 180 | 240 | 280 | 340 | 380 | |

| Roll diameter/2[mm] | 100 | 160 | 200 | 260 | 300 | 360 | 400 | |

| Roll diameter/3[mm] | 120 | 180 | 220 | 280 | 320 | 380 | 420 | |

| Roll ring width [mm] | 60 | 80 | 150 | 150 | 150 | 200 | 200 | |

| Mill type | EM 30 | EM 60 | EM 100 | EM 120 | |

| Edge roll | Rolling force [kN] | 30 | 60 | 100 | 120 |

| Roll diameter/1[mm] | 70 | 110 | 150 | 190 | |

| Roll diameter/2[mm] | 80 | 120 | 160 | 200 | |

| Roll diameter/3[mm] | 90 | 130 | 170 | 210 | |

| Roll ring width [mm] | 40 | 80 | 80 | 100 | |

PROPERTIES AND FEATURES:

Extendable modular machine concept

High precision Servo-Mechanic screw down

Rigid and heavy-duty roll stand

Automatic groove displacement

Mill drive as Mono and Twin drive with infinitely variable speed range

Rolls available in forged steel version, HSS or with tungsten carbide ring

Machines available with different type of lubrication (flood cooling or minimum quantity lubrication)

High accuracy thickness and width measurement – contact and laser gauges

Full range of winding systems

Wire tension control by means of dancer accumulator, dancer, capstan and caterpillar

Inline surface finishing and cleaning

SOFTWARE AND CONTROL SYSTEMS:

Fully digital control system and diagnostics

Pre-calculation and storage of pass schedules

Fully automatic machine setup

Monitoring of torques, temperature, adjustment forces and wire tensions

Felss Edge Device – Your step into Industry 4.0

Active thickness and width regulation

Trend and cascade control

MODULAR MACHINE DESIGN:

Easy to maintain:

Automatic roll changes

Central lubrication system

Predictive warning of critical machine status

Electronic overload protection

Design variants:

Spindle or flange coiling technology as well as spreadable mandrels for coreless winding

Number of Flat Wire Rolling Mills can be extended infinitely thanks to modular machine stand design

Dancer accumulator and dancer in servo design for highly dynamic applications

Non-driven or driven edge rolls

Intelligent wire guidance systems for an easy machine setup and process control

- View as

Electromagnetic Wire Rolling Mill

Electromagnetic wire rolling mill is a kind of equipment used to process metal wire into electromagnetic wire. It is mainly used to produce various specifications of electromagnetic flat wire. It is widely used in wire and cable, automotive parts, electronics and other fields.

Read MoreSend InquiryPhotovoltaic Welding Strip Rolling Mill

The photovoltaic welding strip rolling mill produced by the flat wire mill is a special flat wire product used to connect solar cells in photovoltaic modules. It is composed of copper substrate and surface coating. Copper substrate is usually high-purity oxygen free copper or T2 red copper, with copper content ≥ 99.99% and conductivity ≥ 98%. It has good conductivity and certain strength, which can ensure efficient current transmission.

Read MoreSend Inquiry