- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

- Esperanto

- Afrikaans

- Català

- שפה עברית

- Cymraeg

- Galego

- Latviešu

- icelandic

- ייִדיש

- беларускі

- Hrvatski

- Kreyòl ayisyen

- Shqiptar

- Malti

- lugha ya Kiswahili

- አማርኛ

- Bosanski

- Frysk

- ភាសាខ្មែរ

- ქართული

- ગુજરાતી

- Hausa

- Кыргыз тили

- ಕನ್ನಡ

- Corsa

- Kurdî

- മലയാളം

- Maori

- Монгол хэл

- Hmong

- IsiXhosa

- Zulu

- Yoruba

- অসমীয়া

- ଓଡିଆ

- Punjabi

- پښتو

- Chichewa

- Samoa

- Sesotho

- සිංහල

- Gàidhlig

- Cebuano

- Somali

- Тоҷикӣ

- O'zbek

- Hawaiian

- سنڌي

- Shinra

- Հայերեն

- Igbo

- Sundanese

- Lëtzebuergesch

- Malagasy

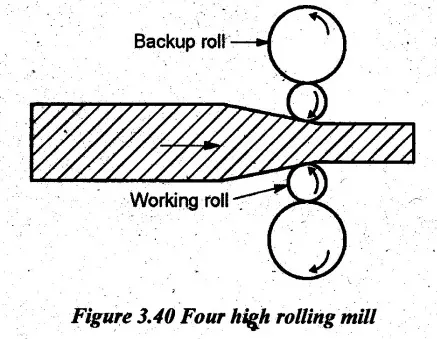

4-Roll Rolling Mill

Send Inquiry

Hot & Cold Rolling Switchable

High-Precision Multi-Batch Rolling Solutions

Flexible Tandem Production Lines for Efficient Manufacturing

The GRM 4-Roll Rolling Mill series is widely used in the steel and non-ferrous metal industries for its high-precision rolling and excellent and stable surface quality.

Compared with the GRM two-roll mill, the four-roll mill can more effectively control the flatness of the strip, reduce bending deformation, and thus improve product accuracy.

• Multi-Stand Configuration: Capable of tandem arrangement with 2 to 7 stands, enabling efficient continuous production.

• Versatile Material Compatibility: Supports flexible switching between cold and hot rolling processes for carbon steel, stainless steel, and non-ferrous metals.

• Precision Rolling Control: Achieves thickness tolerance accuracy of ±0.003mm, meeting high-precision and multi-batch rolling requirements.

• Wide Processing Capability: Accommodates coil widths from 50 to 450mm, with a maximum rolling force of 1200kN, covering cross-industry applications.

Core Advantages

• Hot & Cold Rolling Integration: Switch modes rapidly to match material requirements.

• Reversible Rolling System: Space-saving design with automated feeding for continuous operation.

• Smart Control: Dual servo screw-down & hydraulic roll change for minimal downtime.

Applications

| Field | Scenarios |

| Steel Industry | Production of hot-rolled and cold-rolled carbon steel strips |

| Non-Ferrous Metal Processing | Precious metal strips (e.g., titanium, nickel alloys) |

| Electronics and Electrical Industry | Manufacturing of lithium battery electrodes (e.g., aluminum foil, copper foil rolling) |

| Automotive and Aerospace Industry | Production of lightweight aluminum and magnesium alloy sheets |

Technical Specifications

| Parameter | Specification |

| Material | Copper, stainless steel, carbon alloy |

| Roller diameter | 40-320mm |

| Max. Rolling Force | 1200kN |

| Rolling Speed | 1200 m/min |

| Entry Thickness | 15–20 mm |

| Exit Thickness | 0.5–2.0 mm |

| Thickness Tolerance | ±0.03 mm (Cold Rolling) |

Note: The above parameters may change due to continuous product improvements; please refer to each product’s manual for exact specifications.

• Induction Heating Rolls: Precise temperature control for high-strength alloys

• Coiler Expansion Module: Customized to Client Requirements

• Industry 4.0 Interface: IoT-enabled production analytics

Why Choose Us?

• Global Support: 24/7 remote assistance

• Certifications: CE, ISO 9001 compliant

• Tailored Solutions: Material-specific rolling profiles & tension control

Contact Us for Customized Solutions

Email: solutions@grm-machinery.com

Powering Tomorrow’s Manufacturing – GRM Mills Redefine Precision Rolling