- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

- Esperanto

- Afrikaans

- Català

- שפה עברית

- Cymraeg

- Galego

- Latviešu

- icelandic

- ייִדיש

- беларускі

- Hrvatski

- Kreyòl ayisyen

- Shqiptar

- Malti

- lugha ya Kiswahili

- አማርኛ

- Bosanski

- Frysk

- ភាសាខ្មែរ

- ქართული

- ગુજરાતી

- Hausa

- Кыргыз тили

- ಕನ್ನಡ

- Corsa

- Kurdî

- മലയാളം

- Maori

- Монгол хэл

- Hmong

- IsiXhosa

- Zulu

- Yoruba

- অসমীয়া

- ଓଡିଆ

- Punjabi

- پښتو

- Chichewa

- Samoa

- Sesotho

- සිංහල

- Gàidhlig

- Cebuano

- Somali

- Тоҷикӣ

- O'zbek

- Hawaiian

- سنڌي

- Shinra

- Հայերեն

- Igbo

- Sundanese

- Lëtzebuergesch

- Malagasy

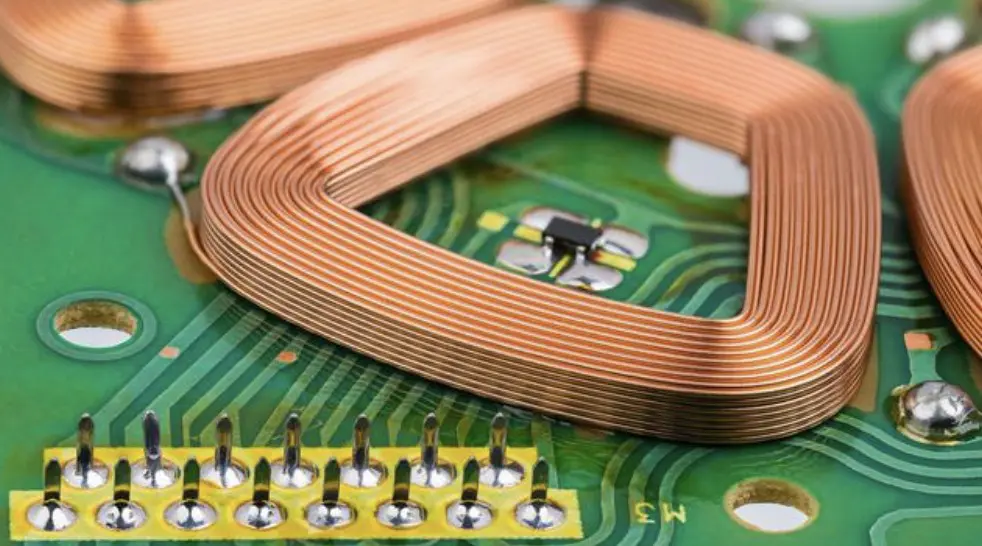

Why Is the Electromagnetic Wire Rolling Mill Essential for Modern Wire Production?

2025-09-02

In today's highly competitive manufacturing industry, the demand for precision and efficiency has never been greater. One of the most advanced solutions for processing metal wires is the Electromagnetic Wire Rolling Mill. This equipment is designed to meet the challenges of producing high-quality electromagnetic wires with excellent dimensional accuracy, smooth surfaces, and consistent performance. As a manufacturer, I always ask myself: how can we ensure better wire quality while maintaining cost efficiency? The answer lies in adopting the latest rolling technology.

What Is the Role of an Electromagnetic Wire Rolling Mill?

The Electromagnetic Wire Rolling Mill plays a crucial role in shaping and refining metal wires used in motors, transformers, and electrical applications. By using electromagnetic force combined with rolling technology, the equipment guarantees precise diameter control and reduces material waste.

Key roles include:

-

Reducing wire diameter with accuracy

-

Improving conductivity and mechanical strength

-

Enhancing wire surface finish

-

Ensuring high-speed and continuous production

How Effective Is the Use of This Equipment?

When I first considered introducing such advanced machinery, I wondered: will it truly improve the production process? After actual use, the results were remarkable. The Electromagnetic Wire Rolling Mill not only enhanced product uniformity but also minimized manual intervention.

Main usage effects:

-

Higher productivity with automated operation

-

Superior wire quality with stable rolling pressure

-

Cost savings through reduced material loss

-

Extended equipment lifespan due to durable design

| Parameter | Specification Example |

|---|---|

| Wire Diameter Range | 0.2 – 5.0 mm |

| Rolling Speed | Up to 80 m/min |

| Precision Tolerance | ±0.005 mm |

| Application Industries | Motors, Transformers, Cables |

Why Is It So Important in Wire Manufacturing?

Many customers often ask me: why should we prioritize the Electromagnetic Wire Rolling Mill compared to traditional systems? The importance is clear—without this technology, achieving the level of precision required by today's electrical industry would be nearly impossible.

Importance and function highlights:

-

Guarantees energy-efficient wire production

-

Meets international quality standards

-

Supports mass production without compromising quality

-

Reduces downtime and increases return on investment

My Final Thoughts

The Electromagnetic Wire Rolling Mill is not just a machine; it is an investment in the future of wire production. By combining accuracy, speed, and reliability, it helps manufacturers stay ahead in a fast-paced industry. For us, adopting this equipment was not just about upgrading machinery—it was about upgrading our entire production philosophy.

At Jiangsu Youzha Machinery Co., Ltd., we provide professional-grade Electromagnetic Wire Rolling Mills that are engineered to deliver long-term value and consistent quality. If you are looking for high-performance wire rolling solutions, please feel free to contact us—we are ready to support your production goals with advanced technology and dedicated service.