- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

- Esperanto

- Afrikaans

- Català

- שפה עברית

- Cymraeg

- Galego

- Latviešu

- icelandic

- ייִדיש

- беларускі

- Hrvatski

- Kreyòl ayisyen

- Shqiptar

- Malti

- lugha ya Kiswahili

- አማርኛ

- Bosanski

- Frysk

- ភាសាខ្មែរ

- ქართული

- ગુજરાતી

- Hausa

- Кыргыз тили

- ಕನ್ನಡ

- Corsa

- Kurdî

- മലയാളം

- Maori

- Монгол хэл

- Hmong

- IsiXhosa

- Zulu

- Yoruba

- অসমীয়া

- ଓଡିଆ

- Punjabi

- پښتو

- Chichewa

- Samoa

- Sesotho

- සිංහල

- Gàidhlig

- Cebuano

- Somali

- Тоҷикӣ

- O'zbek

- Hawaiian

- سنڌي

- Shinra

- Հայերեն

- Igbo

- Sundanese

- Lëtzebuergesch

- Malagasy

Industry News

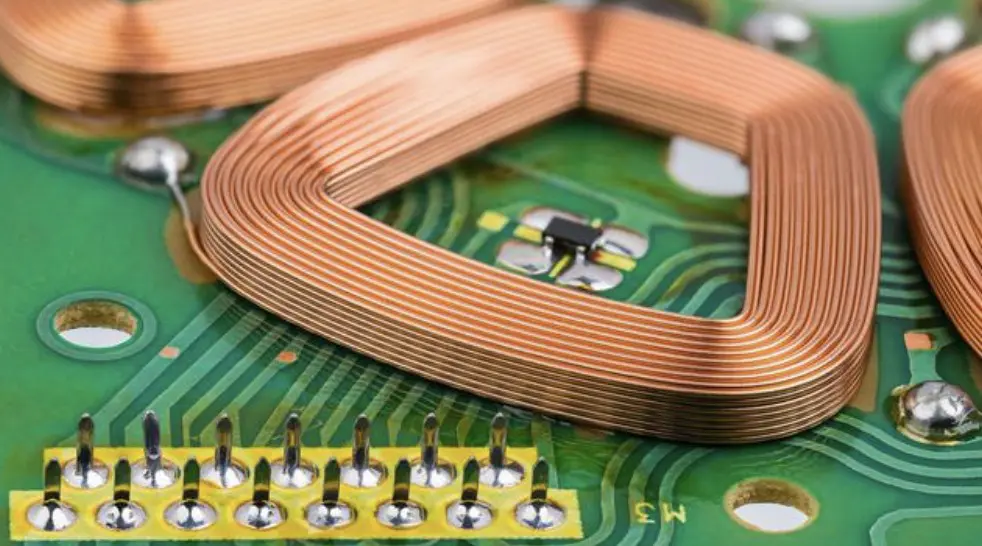

Why Is the Electromagnetic Wire Rolling Mill Essential for Modern Wire Production?

In today's highly competitive manufacturing industry, the demand for precision and efficiency has never been greater. One of the most advanced solutions for processing metal wires is the Electromagnetic Wire Rolling Mill. This equipment is designed to meet the challenges of producing high-quality e......

Read MoreWhat is the function of photovoltaic welding strip rolling mill

The key role of photovoltaic welding strip rolling mill includes ensuring the dimensional accuracy of the strip, optimizing the mechanical properties of the strip, improving production efficiency and product quality, etc., as follows: 1.Ensure the dimensional accuracy of the welding strip: Photov......

Read MoreWhat are the core functions of photovoltaic welding strip rolling mill

The core function of the photovoltaic welding strip rolling mill revolves around "processing metal raw materials into welding strips that meet the requirements of photovoltaic modules", focusing on three core goals: shaping, precision control, and performance assurance. Specifically, it can be div......

Read MoreWhat are the applications of photovoltaic welding strip rolling mill in factories

The photovoltaic welding strip rolling mill is the core equipment in the production process of photovoltaic welding strips, mainly used to process metal wires (such as copper strips) into specific specifications of welding strips that meet the welding requirements of photovoltaic modules through ro......

Read MoreWhat are the applications of photovoltaic welding strip rolling mill in the new energy industry

As a key equipment in the photovoltaic industry chain, the photovoltaic welding strip rolling mill is mainly focused on the application of photovoltaic new energy in the new energy industry. Its core role is to provide key connecting materials - photovoltaic welding strips - for the production of p......

Read MoreWhy do many people choose photovoltaic welding strip rolling mill

Many people choose photovoltaic welding and rolling mills mainly because they have the advantages of high production efficiency, good product quality, and low cost, which can meet the development needs of the photovoltaic industry. Specifically, as follows: High production efficiency: Photovolta......

Read More