- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

- Esperanto

- Afrikaans

- Català

- שפה עברית

- Cymraeg

- Galego

- Latviešu

- icelandic

- ייִדיש

- беларускі

- Hrvatski

- Kreyòl ayisyen

- Shqiptar

- Malti

- lugha ya Kiswahili

- አማርኛ

- Bosanski

- Frysk

- ភាសាខ្មែរ

- ქართული

- ગુજરાતી

- Hausa

- Кыргыз тили

- ಕನ್ನಡ

- Corsa

- Kurdî

- മലയാളം

- Maori

- Монгол хэл

- Hmong

- IsiXhosa

- Zulu

- Yoruba

- অসমীয়া

- ଓଡିଆ

- Punjabi

- پښتو

- Chichewa

- Samoa

- Sesotho

- සිංහල

- Gàidhlig

- Cebuano

- Somali

- Тоҷикӣ

- O'zbek

- Hawaiian

- سنڌي

- Shinra

- Հայերեն

- Igbo

- Sundanese

- Lëtzebuergesch

- Malagasy

News

A new chapter in Sino Indian photovoltaic cooperation: co mapping the future of green energy with Aditya Group

1. Background: The intersection of demand and professional skills The global photovoltaic industry is facing a complex situation of coexistence of protectionist policies and unprecedented demand. India has committed to achieving a renewable energy target of 300 gigawatts by 2030, but its 40%......

Read MoreIn what scenarios is the photovoltaic strip rolling mill suitable for use

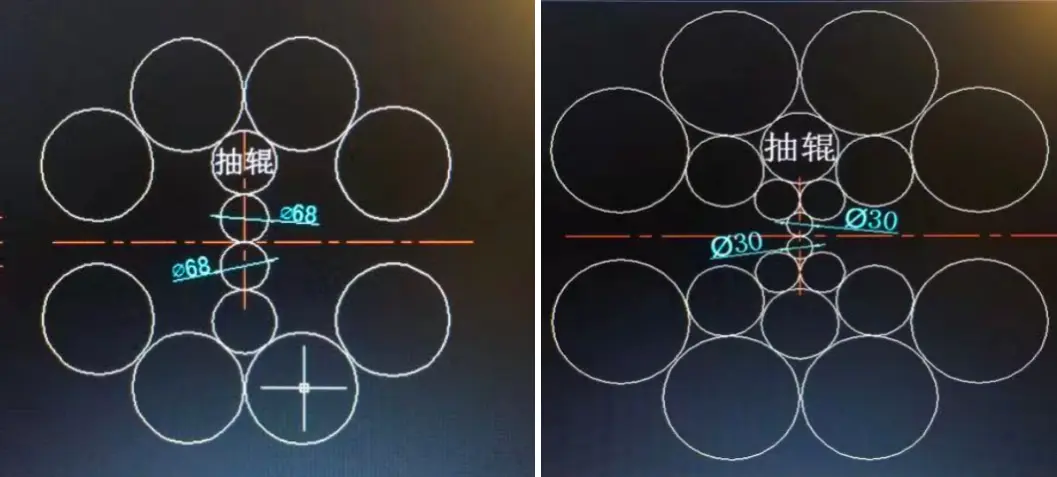

The photovoltaic welding strip rolling mill is the core equipment for photovoltaic welding strip production, mainly used to process copper alloy billets (such as oxygen free copper and tin plated copper) into flat strips with uniform thickness, smooth surface, and micrometer level dimensional......

Read MoreWhat are the advantages of photovoltaic welding strip rolling mill compared to ordinary rolling mill

The core advantage of photovoltaic welding strip rolling mill is designed to meet the special requirements of "high precision, narrow specifications, high conductivity and thermal conductivity" of photovoltaic welding strips. Compared with ordinary rolling mills, it is more suitable for the photovol......

Read MoreWhy Is a Strip Rolling Mill Essential for Modern Metal Processing?

A Strip Rolling Mill is a vital machinery system used in the metal processing industry to reduce the thickness of metal strips while enhancing their mechanical properties. At Jiangsu Youzha Machinery Co., Ltd., we specialize in designing and manufacturing high-performance Strip Rolling Mills to meet......

Read MoreWhere is the precision of Photovoltaic Welding Strip Rolling Mill reflected

The precision of photovoltaic welding strip rolling mill is reflected in multiple aspects, as follows: 1.High precision rolling system: The photovoltaic welding strip rolling mill adopts a servo control system, with a rolling pressure error of ≤± 5N, which can ensure the uniformity of the welding......

Read MoreWhat Makes a 20-Roll Rolling Mill the Key to Precision Metal Processing?

In modern steel and nonferrous metal industries, precision, consistency, and efficiency define product quality and profitability. Among the many pieces of high-end equipment used in rolling operations, the 20-Roll Rolling Mill stands out as one of the most advanced and reliable technologies. It is w......

Read More