- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

- Esperanto

- Afrikaans

- Català

- שפה עברית

- Cymraeg

- Galego

- Latviešu

- icelandic

- ייִדיש

- беларускі

- Hrvatski

- Kreyòl ayisyen

- Shqiptar

- Malti

- lugha ya Kiswahili

- አማርኛ

- Bosanski

- Frysk

- ភាសាខ្មែរ

- ქართული

- ગુજરાતી

- Hausa

- Кыргыз тили

- ಕನ್ನಡ

- Corsa

- Kurdî

- മലയാളം

- Maori

- Монгол хэл

- Hmong

- IsiXhosa

- Zulu

- Yoruba

- অসমীয়া

- ଓଡିଆ

- Punjabi

- پښتو

- Chichewa

- Samoa

- Sesotho

- සිංහල

- Gàidhlig

- Cebuano

- Somali

- Тоҷикӣ

- O'zbek

- Hawaiian

- سنڌي

- Shinra

- Հայերեն

- Igbo

- Sundanese

- Lëtzebuergesch

- Malagasy

What Makes a 20-Roll Rolling Mill the Key to Precision Metal Processing?

2025-11-10

In modern steel and nonferrous metal industries, precision, consistency, and efficiency define product quality and profitability. Among the many pieces of high-end equipment used in rolling operations, the 20-Roll Rolling Mill stands out as one of the most advanced and reliable technologies. It is widely adopted for producing ultra-thin, high-quality metal strips with excellent surface finish and tight thickness tolerance.

At Jiangsu Youzha Machinery Co., Ltd., we have specialized in the design and manufacture of customized 20-Roll Rolling Mills for decades. Our equipment integrates advanced mechanical design, automation control, and hydraulic technology to deliver superior rolling accuracy, longer service life, and optimized production efficiency.

What Is a 20-Roll Rolling Mill and How Does It Work?

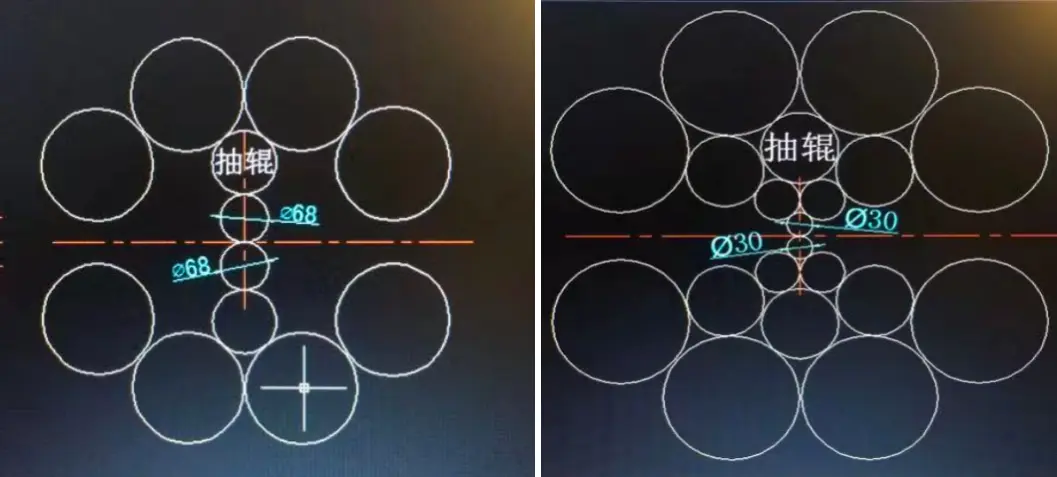

A 20-Roll Rolling Mill—also known as a Sendzimir mill—is a complex structure consisting of twenty rolls arranged in multiple layers to apply uniform pressure on the metal strip during rolling. The roll configuration typically follows a 1–2–3–4 arrangement, meaning one work roll, supported by two first intermediate rolls, three second intermediate rolls, and four backup rolls on each side.

This configuration distributes rolling pressure evenly, minimizes deflection, and ensures high precision. The mill is capable of reducing metal thickness to the micron level, making it ideal for stainless steel, copper, aluminum, and special alloy strip production.

Why Choose a 20-Roll Rolling Mill for Your Production Line?

There are several reasons why manufacturers prefer 20-Roll Rolling Mills over conventional 4-High or 6-High mills:

-

Superior Thickness Control – Achieves strip thickness as low as 0.05 mm with ±0.001 mm tolerance.

-

Exceptional Surface Quality – Delivers mirror-like finishes for demanding applications.

-

High Rolling Pressure – Handles strong, hard-to-deform materials such as stainless steel and titanium.

-

Long Roll Life – Multi-roll support reduces wear on the working rolls.

-

Energy Efficiency – Optimized hydraulic and drive systems reduce energy consumption.

What Are the Main Technical Parameters of the 20-Roll Rolling Mill?

Below is a general specification table for the 20-Roll Rolling Mill manufactured by Jiangsu Youzha Machinery Co., Ltd.

| Parameter | Specification Range | Description |

|---|---|---|

| Model | ZR21-44, ZR22-50, ZR23-68 | Customized models available |

| Max Rolling Width | 600 – 1600 mm | Depending on product design |

| Rolling Thickness Range | 0.05 – 3.0 mm | Ultra-thin precision rolling capability |

| Max Rolling Force | Up to 2000 tons | Suitable for high-strength materials |

| Rolling Speed | 100 – 1200 m/min | Variable speed control for production flexibility |

| Drive Type | Electric / Hydraulic | Energy-efficient and precise control systems |

| Automatic Gauge Control (AGC) | ±0.001 mm | Ensures accurate thickness consistency |

| Material Compatibility | Stainless steel, copper, aluminum, titanium | Wide range of applications |

| Control System | PLC + HMI + Data Recorder | Intelligent operation and monitoring |

How Does the 20-Roll Rolling Mill Improve Production Efficiency?

The 20-Roll Rolling Mill optimizes every stage of the rolling process through advanced automation and control systems. Automatic Gauge Control (AGC) ensures real-time adjustment of roll pressure, while the Hydraulic Automatic Flatness Control (AFC) system maintains uniform strip flatness.

In addition, the mill's high-speed drive system shortens rolling time, and its compact roll structure allows for quick roll changeovers. The integration of data acquisition and monitoring technology enables predictive maintenance, minimizing downtime and maximizing throughput.

Where Can a 20-Roll Rolling Mill Be Used?

The 20-Roll Rolling Mill is essential in industries requiring precision metal strips, including:

-

Stainless steel production – For high-end appliances, kitchenware, and automotive parts.

-

Copper and brass processing – Used in electronic connectors, conductive sheets, and decorative materials.

-

Aluminum foil and thin sheet – Ideal for packaging, aerospace, and energy applications.

-

Special alloy rolling – For nickel-based alloys, titanium, and other high-performance metals.

FAQ: Common Questions About the 20-Roll Rolling Mill

Q1: What makes the 20-Roll Rolling Mill different from a 4-High or 6-High mill?

A1: The 20-Roll Rolling Mill uses multiple backup rolls to support the small working rolls, ensuring superior shape control and minimal deflection. This allows for ultra-thin rolling with higher accuracy compared to 4-High or 6-High mills.

Q2: Can the 20-Roll Rolling Mill handle different materials?

A2: Yes. It is suitable for a variety of metals, including stainless steel, copper, brass, aluminum, and titanium alloys. The system can be customized to meet specific material hardness and width requirements.

Q3: How does Jiangsu Youzha Machinery Co., Ltd. ensure quality and performance?

A3: Every 20-Roll Rolling Mill produced by Jiangsu Youzha Machinery Co., Ltd. undergoes strict mechanical testing, dynamic balance inspection, and computer-simulated operation analysis to ensure durability, precision, and stability before shipment.

Q4: What after-sales support is available?

A4: The company provides complete after-sales services including on-site installation, operator training, spare parts supply, and remote technical support to ensure smooth and efficient mill operation.

Why Trust Jiangsu Youzha Machinery Co., Ltd. for Your 20-Roll Rolling Mill Needs?

Jiangsu Youzha Machinery Co., Ltd. is a leading manufacturer with rich experience in designing high-precision rolling mills. We provide tailor-made 20-Roll Rolling Mill solutions for global customers based on specific material requirements and production capacity. Our R&D team continuously improves structural design, automation, and control systems to help our clients achieve higher productivity and better quality.

We understand that every rolling operation demands precision, stability, and efficiency — and that's exactly what we deliver. Whether you're upgrading an existing production line or building a new facility, our engineering expertise and full-service support make us your trusted partner in metal rolling technology.

If you're interested in learning more about the 20-Roll Rolling Mill, please contact Jiangsu Youzha Machinery Co., Ltd. for customized solutions, technical consultation, and pricing information.